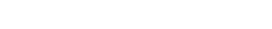

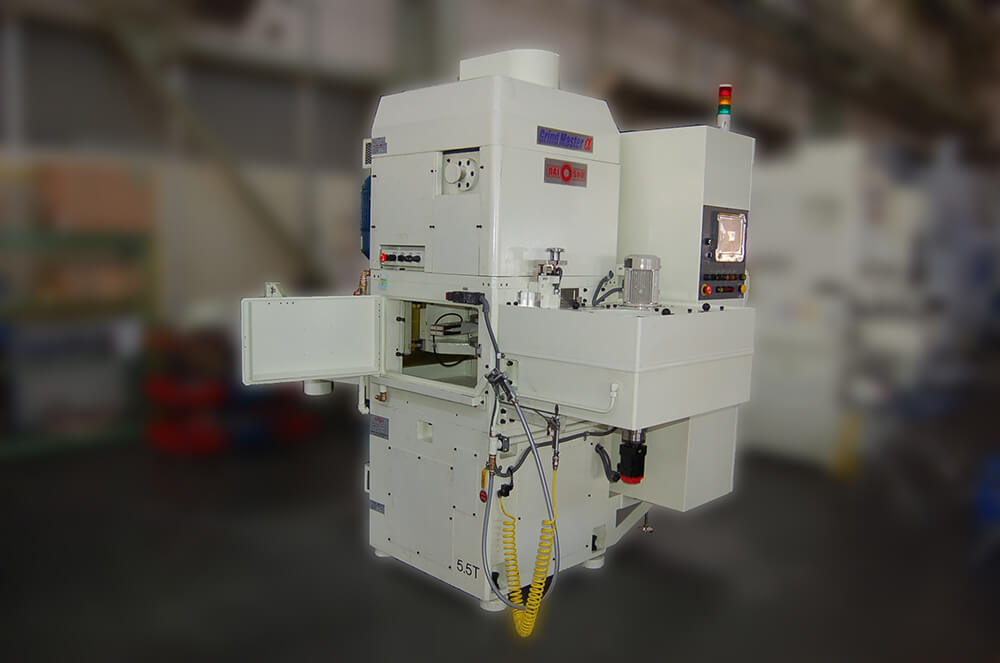

Vertical type double disc grinding machine

GRV series

A vertical double-disk grinding machine is a grinding machine in which two grinding wheel shafts face each other vertically. There are a variety of machining patterns: heavy to high precision, and mass to small scale productions.

Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

SPEC

| Model | Wheel Diameter | Size | Weight | Main Motor |

|---|---|---|---|---|

| GRV-305 | φ305mm | W1,550 × L1,625 × H2,200 | 5,500Kg | 5.5kW |

| GRV-355 | φ355mm | W1,550 × L1,625 × H2,200 | 5,500Kg | 7.5kW |

| GRV-450 | φ455mm | W1,550 × L1,625 × H2,200 | 5,500Kg | 11kW |

| GRV-510 | φ510mm | W1,550 × L1,625 × H2,200 | 5,500Kg | 15kW |

| GRV-585 | φ585mm | W1,900 × L2,700 × H2,800 | 12,000Kg | 22kW |

| GRV-760 | φ760mm | W2,700 × L2,700 × H3,200 | 15,000Kg | 30kW |

PROCESSING METHOD

-

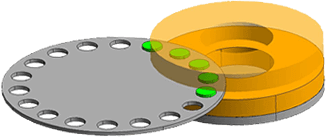

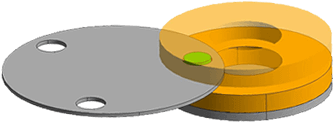

Rotary carrier system (C)

Workpieces in pockets of the carrier are ground while the carrier is indexing between the grinding wheels. It is intended for workpieces with relatively small stock removals, but it can be used for various shapes. It is designed to keeping workpieces running continuously, relying on automation for high production.

e.g., piston rings, washers, plates, bearings, etc. -

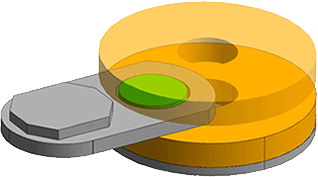

Oscillation carrier system (Ci)

The carrier oscillates and the top grinding wheel in-feeds. It is suitable for workpieces that require a large amount of stock removal and precision. It goes well with automation like the rotary carrier.

e.g., retaining plate, valve plate, etc. -

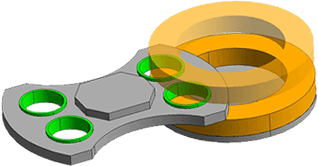

Work rotation index system (G1)

In-feed grinding is performed by forcibly rotating the workpiece. It is suitable for workpieces that require high precision.

Multiple pockets can shorten the processing time.

e.g., connecting rods, cam rings, rotors, gears, cylinders, etc. -

Work rotation index system (G2)

In-feed grinding is combined with forced rotation of the workpiece. It is suitable for workpieces that require high precision. A two station design, one for loading /unloading and the other for grinding, loses no time in loading and unloading.

e.g., connecting rods, cam rings, rotors, gears, cylinders, etc. -

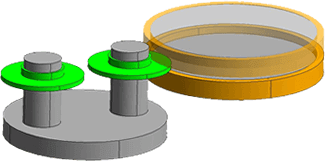

Index table work drive (IT2)

In-feed grinding is combined with forced work rotation while the top of the workpiece on the fixture is clamped.

e.g., disk rotor -

Vertical through feed system (A)

Workpieces continuously go through the guide rail between the grinding wheels to grind them. It is suitable for workpieces that require a small amount of space and high productivity.

e.g., blades, piston rings, knives, bearing inner and outer rings, etc.

Other grinding methods are available upon your requests.

In the past 70 years of experience, we have ground a variety of workpieces

to meet the requests of our customers.

Please contact us with any questions or for additional information.