FEATURES

About Peeling Machines

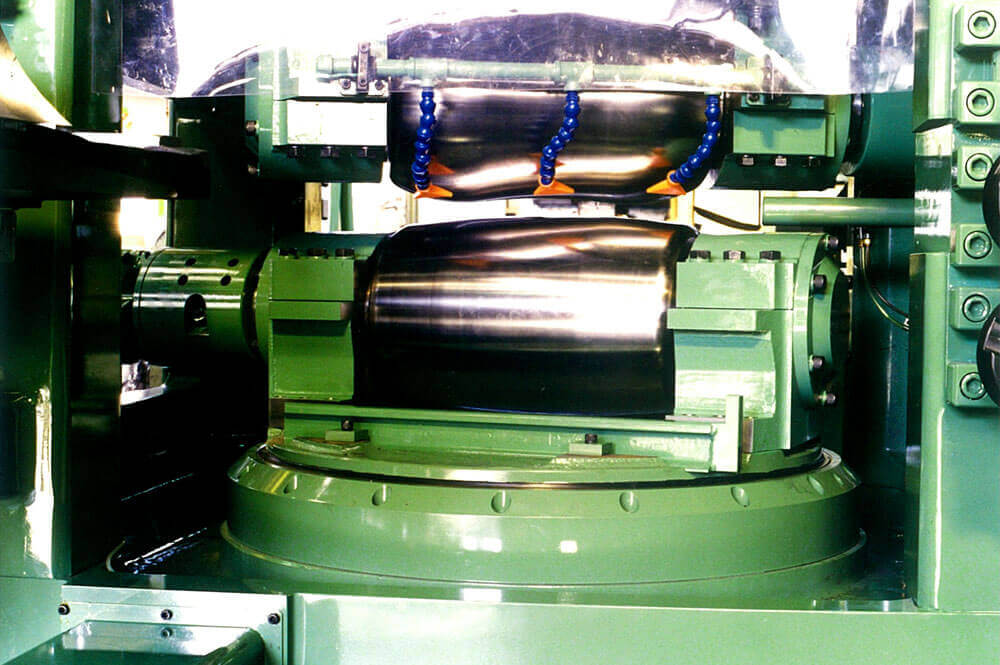

A peeling machine removes the decarburized layers, scratches, or defective hardened layers on the surface of the cold/hot rolled bars. A continuously feeding system of bars loses no time in loading and unloading.

Therefore, it is suitable for mass production. The chips can be reused.

Lineup

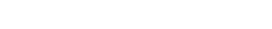

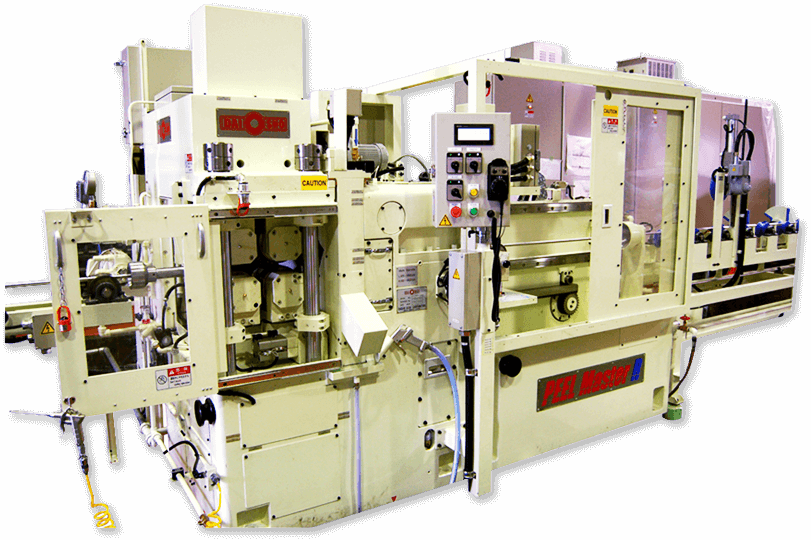

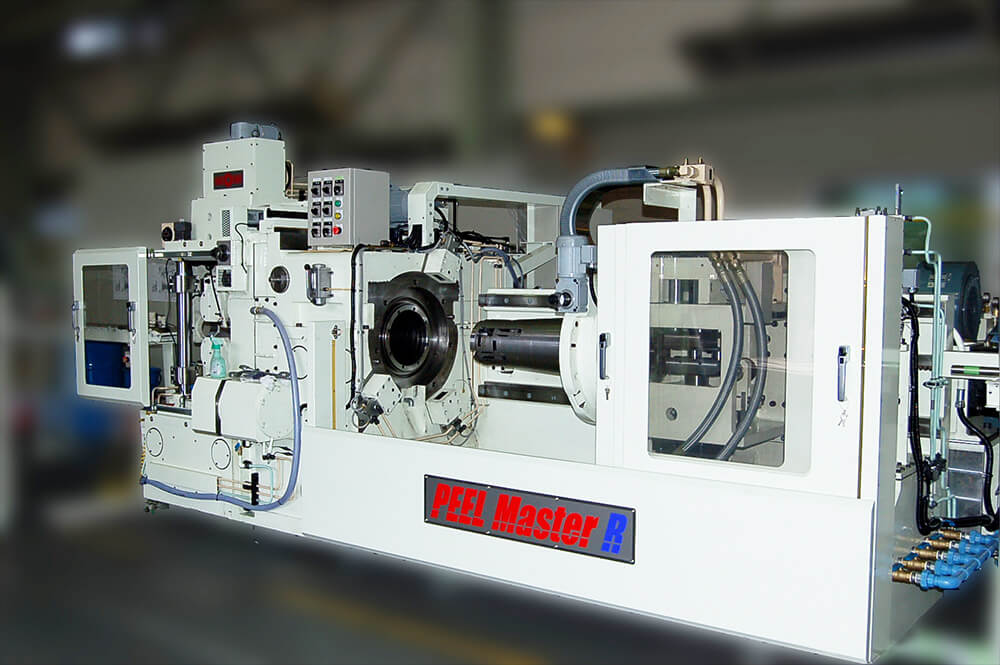

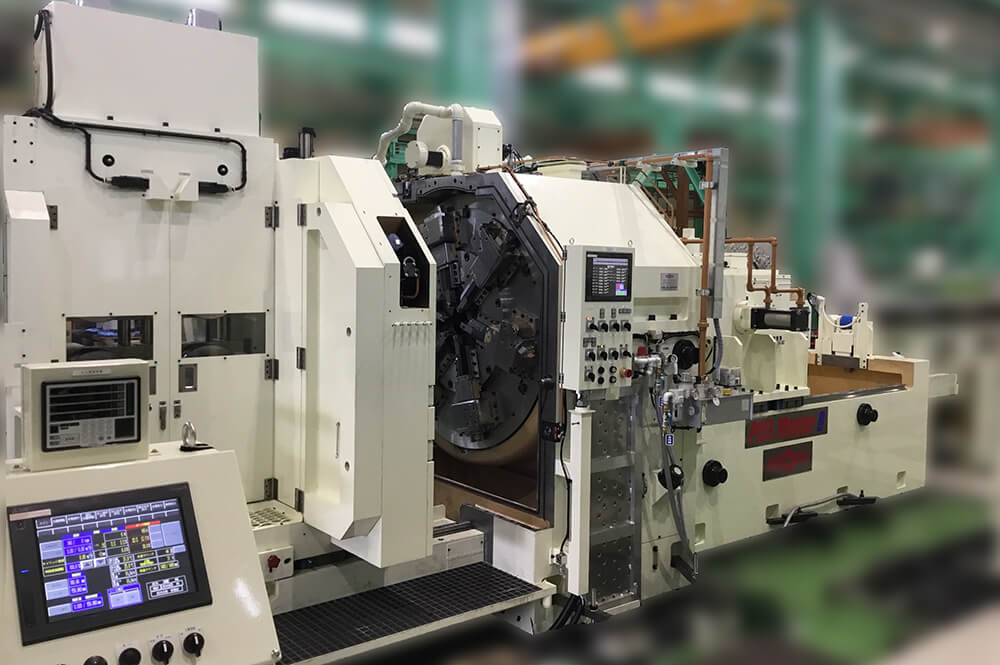

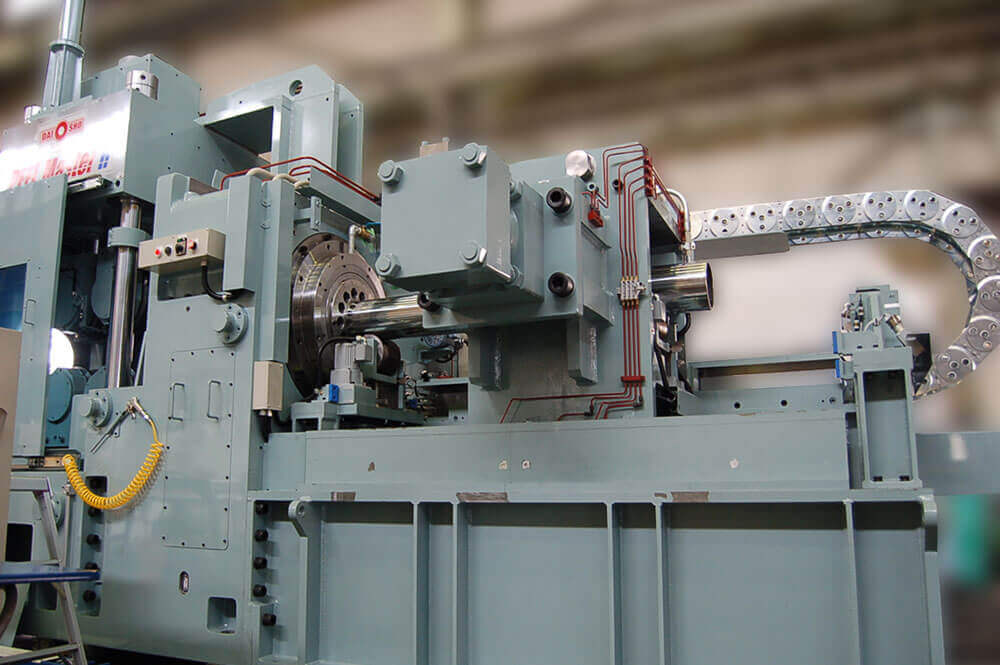

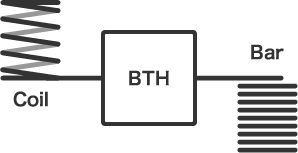

- BTH/BTM series - “Bar to Bar” Peeling Machines

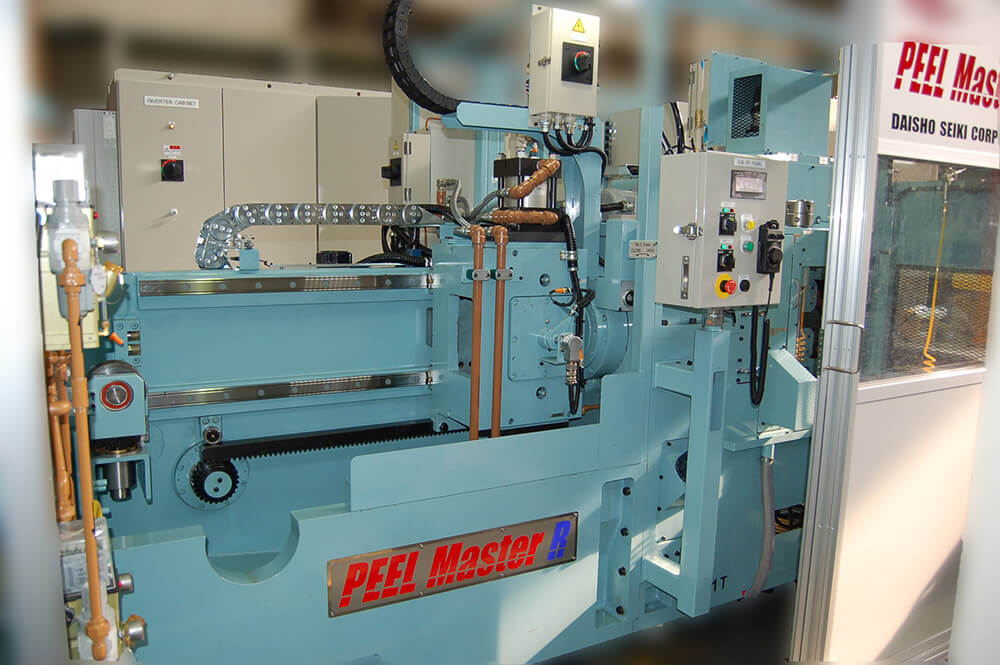

- CPM series - “Coil to Coil” peeling machines (wire shavers) with planetary polishers and re-coilers

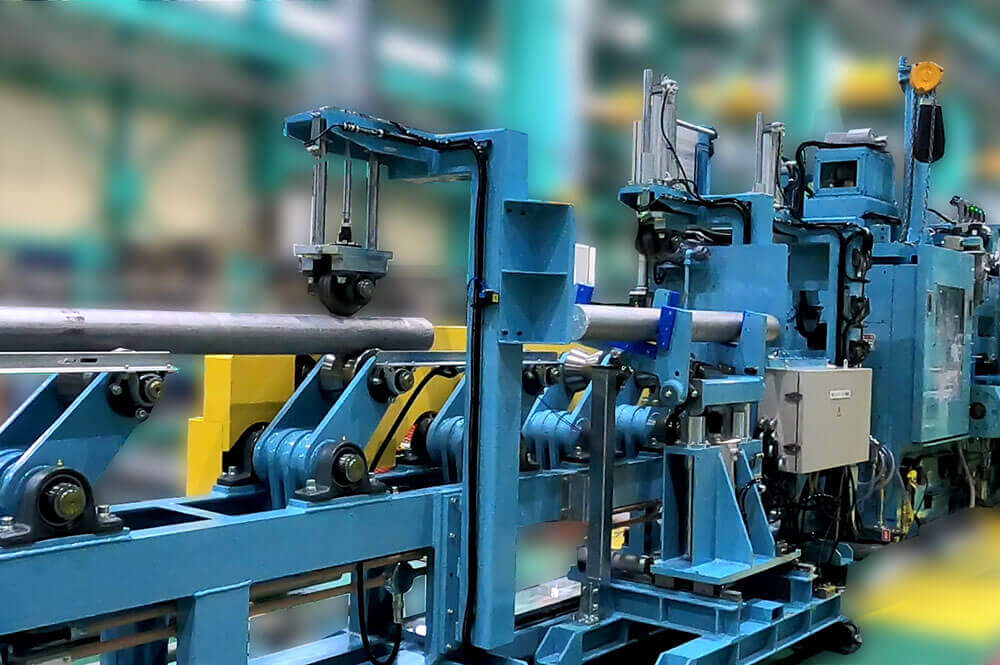

- CBH series - “Coil to Bar” peeling and cut machines, which control OD sizes and cut off the wire to the dimension in length

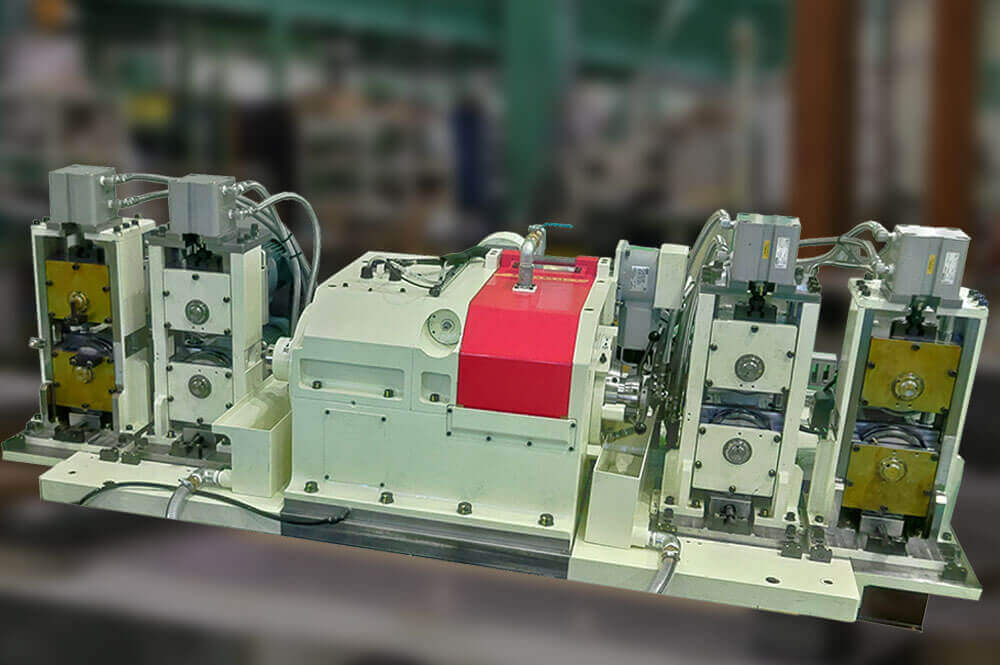

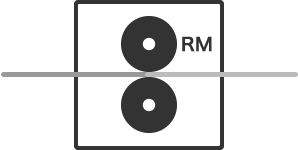

- RM series - Two-roll burnishers and straighteners with the ability to straighten black and bright bars and eliminate small surface irregularities to improve the surface finish.

We are well-capable of designing, engineering and manufacturing machines

in line with a customer’s requests.

“FIVES Daisho Seiki's Product lineup is not limited to the “Bar to Bar” peeling machine, but also includes a “Coil to Bar” machine that continuously feeds coiled materials, turns them into certain sizes, and cuts them into predetermined lengths, and a “Coil to Coil” machine with a coil take-up block.” We are also engaged in the design and manufacture of two-roll burnishers and straighteners with the ability to straighten black and bright bars and eliminate small surface irregularities to improve the surface finish.

-

BTH/BTM

-

CPM

-

CBH

-

Straightening

SPEC

| Model | Size range | Feeding rate | Main motor | Weight |

|---|---|---|---|---|

| BTH-25R | φ6~25 | Max.50 | 45 kW Inverter | 12,000 |

| BTH-35R | φ10~35 | Max.50 | 75 kW Inverter | 14,000 |

| BTH-60R | φ12~60 | Max.50 | 75 kW Inverter | 28,000 |

| BTH-80R | φ20~80 | Max.50 | 150 kW Inverter | 32,000 |

| BTH-125R | φ30~125 | Max.30 | 200 kW Inverter | 36,000 |

| BTH-160R | φ40~160 | Max.30 | 300 kW Inverter | 39,500 |

| BTH-200R | φ80~200 | Max.20 | 300 kW Inverter | 69,000 |

| BTH-280R | φ100~280 | Max.15 | 300 kW Inverter | 73,000 |

| BTH-360R | φ120~360 | Max.10 | 300 kW Inverter | 80,000 |