PRODUCTS

Fives Daisho Seiki K.K. aims to further improve its accuracy and efficiency from heavy cutting to ultra-precision grinding

We manufacture grinding machines to grind faces of automobile parts and bearings, and supply products to automobile subcontractors.

The peeling machine -BTH/RM series efficiently removes scratches and decarburized layers on the surface of raw cold-hot rolled bars.

We have provided business for nearly 70 years since our foundation, and today’s prosperity lies not only in the reliability of our products and

high technological capabilities, but also in the niche sector in the competitive machine tool industry.

We sale our products not only to the companies based in Japan, but also to clients in Asia, United States, Europe, and all over the world.

Going forward, we will continue to supply products to the world with the spirit of “Made in Japan”.

Click the desired product from the following two buttons for more information.

GRINDER

-

Vertical type double disc grinding machine

GRV seriesA vertical double-disk grinding machine is a grinding machine in which two grinding wheel shafts face each other vertically. There are a variety of machining patterns: heavy to high precision, and mass to small scale productions.

GRV series Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

-

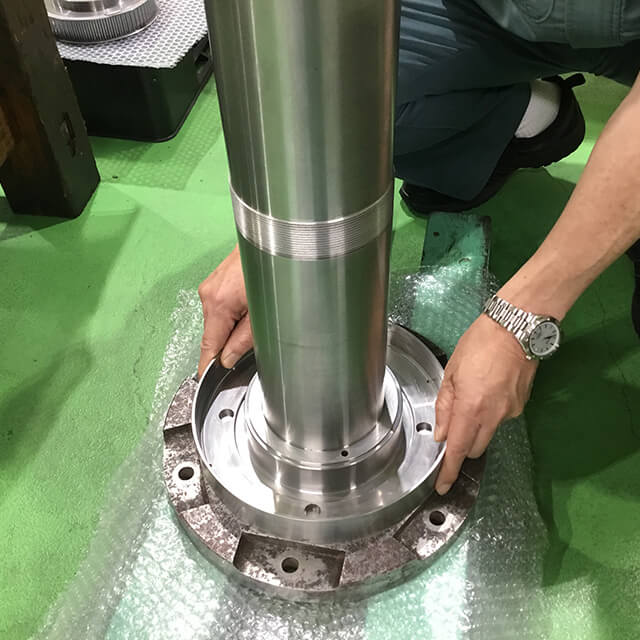

Vertical type single disc grinding machine

GRS seriesA vertical single grinding machine is a grinding machine in which a grinding wheel shaft is vertically disposed only on the upper side, and grinds one side of a workpiece. Vertical single disc grinders are generally used to process workpieces with complicated shapes, tighter tolerances and location requirements.

GRS series Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

-

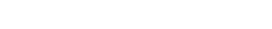

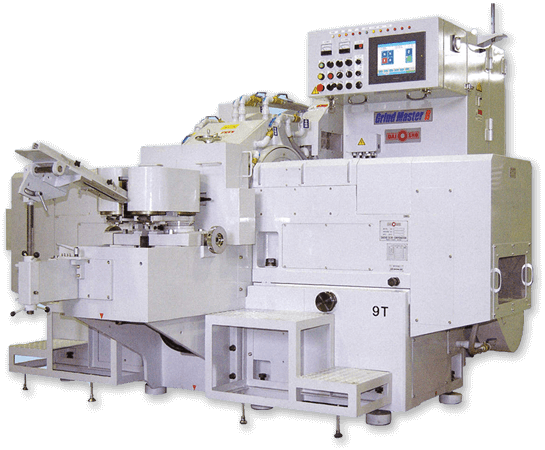

Horizontal type double disc grinding machine

DRG seriesA horizontal double-disk grinding machine is a grinding machine in which two grinding wheel shafts face each other horizontally. It is suitable for use in heavy grinding and mass production, which requires a large amount of stock removal, but it is also suitable for high precision grinding.

DRG series Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

FEATURES

-

Rigid high grade cast iron frame with minimum vibration

We have improved the structure from conventional to rib-less and increased the wall thickness. As a result, high rigidity and strength were achieved. We have succeeded in minimizing thermal distortion and vibration during grinding.

-

Precise grindstone cutting mechanism and control system structure

The spindle is fed by direct drive of the servo moter and ultra-precision ball screw, which eliminates backlash and ensures smooth feed.

-

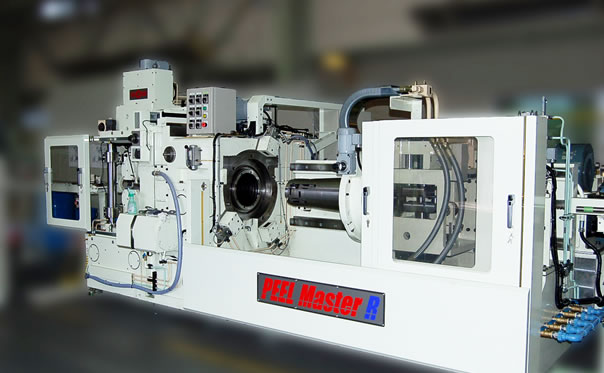

Solid one-piece design spindle

By integrating the flanges, the flanges have better end surface deflection and more stable accuracy than those obtained by joining the components together. Performance is maintained semi-permanently by integrally forging the main spindle, which is the heart of the grinder.

-

Easy-to-work tilting mechanism

Maintenance-free adjustable grinding wheel tilting mechanism with a solid locking system. There is no need to suspend process or provide internal training for adjusting the grindstone.

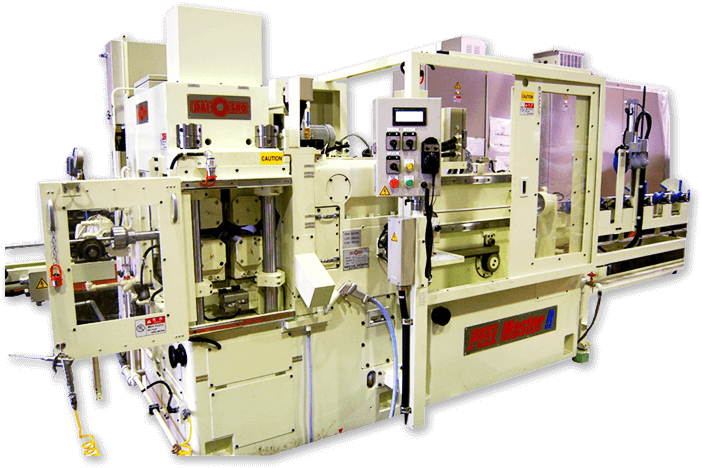

BAR PEELING

-

Peeling machine

BTH Corresponding Work Pieces

- Ferrous, non-ferrous

- Special steel

- Alloyed steel

- Copper and titanium

- Inconel

- Hollow materials (pipe materials), etc.

Fives Daisho Seiki is

- The only peeling machine manufacturer in Japan

- The max. stock removal is 15mm in diameter.

AFTER SERVICE

Customer Service Policy

Our customer service department provides 360-degree after-sales support to help you make the most of your purchases. A team of solutions experts is standing by to immediately respond to urgent problems or other emergencies, replace a part, provide maintenance, overhaul aging components, troubleshoot a problem, and more. Fives Daisho Seiki can also help you incorporate new production processes, streamline for better productivity, relocate machinery due to changes in production lines, etc. Contact us by phone, email, or fax to find out more about machine diagnosis, maintenance, overhauls, modifications, or whatever else you need.

We accecpt other companies' products as well.

First of all, please feel free to consult us.

TEL.+81-797-62-5500

Reception time: from 9:00 to 17:30 on weekdays

In case of an emergency, you will be consulted anytime.