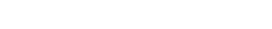

Horizontal type double disc grinding machine

DRG series

A horizontal double-disk grinding machine is a grinding machine in which two grinding wheel shafts face each other horizontally. It is suitable for use in heavy grinding and mass production, which requires a large amount of stock removal, but it is also suitable for high precision grinding.

Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

SPEC

| Model | Wheel Diameter | Size | Weight | Main Motor |

|---|---|---|---|---|

| DRG-305 | φ305mm | W2,280 × L1,540 × H1,940 | 4,500Kg | 5.5kW |

| DRG-355 | φ355mm | W2,280 × L1,540 × H1,940 | 4,500Kg | 7.5kW |

| DRG-380 | φ380mm | W2,280 × L1,540 × H1,940 | 4,500Kg | 7.5kW |

| DRG-585 | φ585mm | W3,060 × L2,010 × H2,460 | 9,000Kg | 22kW |

| DRG-760 | φ760mm | W3,600 × L2,750 × H2,780 | 15,000Kg | 30kW |

| DRG-915 | φ915mm | W3,600 × L2,750 × H3,000 | 17,000Kg | 37kW |

PROCESSING METHOD

-

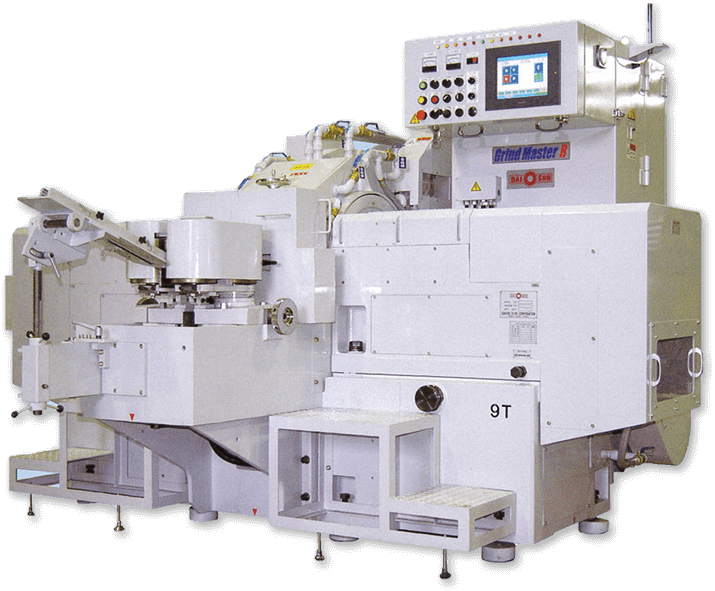

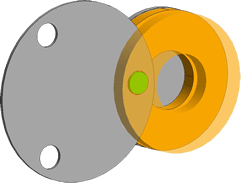

Through-feed method (A)

Workpieces continuously go through the guide rail between the grinding wheels to grind them. It is suitable for workpieces that require a small amount of stock removal and high productivity.

e.g., blades, piston rings, knives, bearing inner and outer rings, etc. -

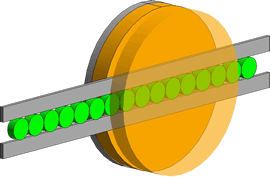

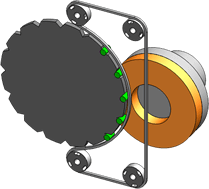

Horizontal rotary carrier system (C)

Workpieces in pockets of the carrier are ground while the carrier is indexing between the grinding wheels. It is designed to keep workpieces running continuously, relying on automation for high production.

e.g., connecting rods, pinion gears, rings, blades, etc. -

Horizontal rotary index infeed system (Cx)

A grinding wheel in-feeds while workpieces in the pockets of the carrier are fed between the grinding wheels. It is suitable for workpieces that require a large amount of stock removal and precision.

e.g., connecting rod, pinion gear, etc. -

Lateral rotary carrier/belt clamping system (C)

It is suitable for machining a workpiece which requires tight tolerance on squaremess to the locatoin.

e.g., cylindrical or prismatic work, etc. -

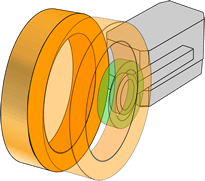

Gun feed system (E)

Place the workpiece in the jig, and perform in-feed grinding while moving the workpiece forward and backward in a clamped state.

e.g., shift forks, diaphragm springs, etc.

Other grinding methods are available upon your requests.

In the past 70 years of experience, we have ground a variety of workpieces

to meet the requests of our customers.

Please contact us with any questions or for additional information.